Engine additive could help save on gas

A research team from Texas used the CLS to develop a new additive for automotive engine oil that reduces harmful emissions, increases fuel efficiency and improves durability.

By Sarath PeirisClose up of someone pouring engine oil into an engine.

A research team from Texas used the Canadian Light Source (CLS) at the University of Saskatchewan to develop a new additive for automotive engine oil that reduces harmful emissions, increases fuel efficiency and improves durability.

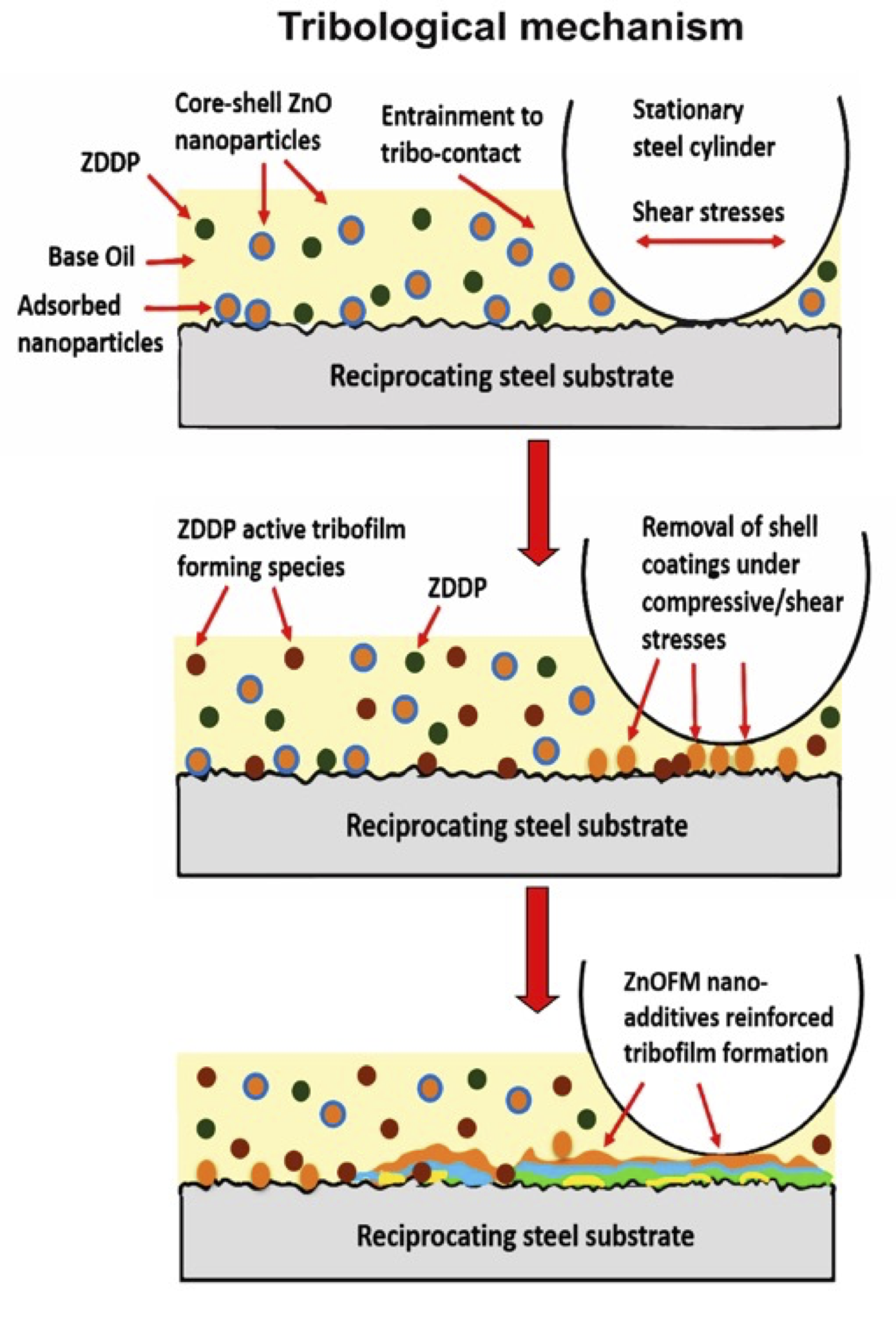

The team set out to develop an alternative for phosphorus-based engine oil additives, especially a compound called ZDDP that has been in use for the past 90 years because it is cheap and offers some engine protection. Conventional additives like ZDDP form a thin film on the surface of moving parts to reduce friction.

“A big problem with these phosphorus-based additives is they form the same film on catalytic converters in vehicles, increasing greenhouse gas emissions,” said Dr. Pranesh Aswath, a materials science engineer who is interim provost and vice-president academic affairs at the University of Texas at Arlington (UTA).

With U.S. federal regulations mandating emission reductions and higher fuel standards in the auto sector, there is pressure to reduce phosphorus and sulphur additives in engine oils.

The challenge is to reduce the amount of phosphorous in oil while maintaining the additive’s ability to form the thin coatings that protect the right engine parts against the tremendous heat and pressure in which they work.

Aswath’s group studied how these coatings are formed on engine surfaces.

“That’s where the CLS beamlines are so important,” said Aswath, whose graduate students have been conducting team research at the synchrotron for the past dozen years. “The beamlines are really surface sensitive and give you very detailed information on the chemistry of the elements present in these films.”

Aswath is especially appreciative for the VLS-PGM beamline, which he describes as “the best low energy beamline, hands-down, in the Western Hemisphere.” The team used the VLS-PGM and SXRMB beamlines at the CLS to get a complete look at what was happening with the coatings.

The researchers have developed an innovative alternative. They are using an phosphorous-free additive that has environmentally-friendly compounds, with an acrylic coating. The additive actually makes the films more robust and less likely to fail compared to conventional methods.

“We want the nanoparticles to be relatively benign when they are in the engine oil, but when they come to the point of contact in surfaces where high temperatures and pressure come into play, they would essentially break apart and form robust films,” said Aswath.

The team’s findings, reported in Elsevier and Langmuir, show highly promising results for replacing or reducing the phosphorous content in existing lubricants. This new engine additive could help the environment and our wallets when we fill up on gas.

Vyavhare, Kimaya, Richard B. Timmons, Ali Erdemir, Brian L. Edwards, and Pranesh B. Aswath. "Tribochemistry of fluorinated ZnO nanoparticles and ZDDP lubricated interface and implications for enhanced anti-wear performance at boundary lubricated contacts." Wear 474 (2021): 203717. https://doi.org/10.1016/j.wear.2021.203717

Vyavhare, Kimaya, Richard B. Timmons, Ali Erdemir, Brian L. Edwards, and Pranesh B. Aswath. "Robust Interfacial Tribofilms by Borate-and Polymer-Coated ZnO Nanoparticles Leading to Improved Wear Protection under a Boundary Lubrication Regime." Langmuir 37, no. 5 (2021): 1743-1759. https://doi.org/10.1021/acs.langmuir.0c02985

To arrange an interview, contact:

Victoria Schramm

Communications Coordinator

Canadian Light Source

306-657-3516

victoria.schramm@lightsource.ca