Researchers work to reduce failures in hip implants

Using light brighter than the sun to help identify the cause of hip implant failure.

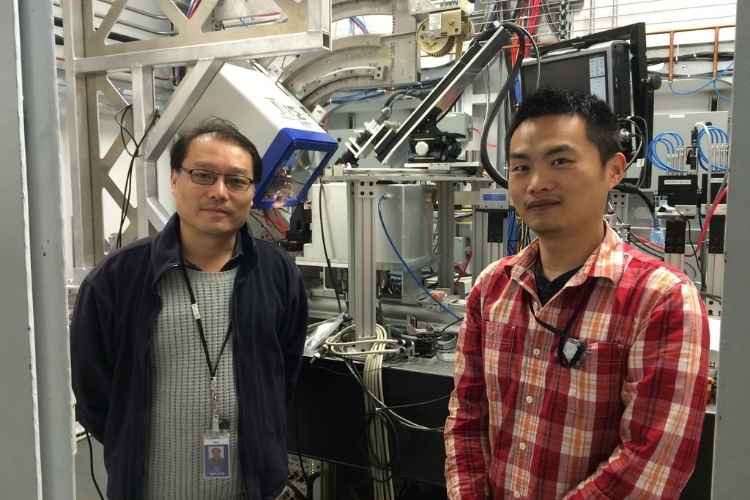

By Colleen MacPhersonVESPERS beamline at the CLS, which was used by the team for this project.

Total hip replacement surgery relieves pain for over one million patients around the world every year, but while it is hugely successful, there is still room for improvement.

Dr. Rizhi Wang is a professor in the Department of Materials Engineering and the School of Biomedical Engineering at the University of British Columbia (UBC) and a researcher at the UBC-affiliated Centre for Hip Health and Mobility. He is part of a team using the Canadian Light Source (CLS) at the University of Saskatchewan to identify the cause of hip implant failure.

A small number of patients will suffer from an implant failure, often years after implantation, that causes various symptoms and will require an implant replacement. “It’s a clinical challenge to understand what causes the problem and how to correct it; this forms the motivation for the current research,” said Wang.

Wang’s team published findings in the journal Materialia, which is the first of a three-stage effort to find a solution.

As an implant breaks down in the body it can shed tiny metal particles and ions and cause what are called adverse local tissue reactions (ALTRs). The team’s research focused on understanding the chemical nature of these damaging particles and precisely how they are produced.

Their study has opened the door for research into how cells react to the particles and cause ALTRs. The third stage will be to improve the design and material selection of implants to mitigate these side effects.

“We needed to solve question one in order to proceed to questions two and three,” he said.

Orthopedic surgeons collected failed implants and tissue samples during hip implant revision surgeries. Dr. Wang’s research team analyzed these samples using the VESPERS beamline at the CLS, which revealed chromium- and phosphate-rich amorphous particles in the tissues. These particles form by corrosion of the implant in the body as well as simple wear and tear on a moving joint.

“The body is a very corrosive environment,” said Wang. When he speaks about this work, he often references the movie Alien where the “blood” of the creature eats through the spacecraft. Human blood is not that aggressive, but when metal is in our body, our immune system will defend against that foreign material.

Having identified the particles and how they form at the CLS, Wang’s team moved to the lab. There, they were able to replicate particle production using a specifically designed wear tester and simulated body fluids.

“We believe that process is close enough to the human environment and the produced particles are good candidates for cell studies,” the second step on the road to “continued design revisions on implants.”

Some of that work is already underway. Wang said his group has connected with a surface engineering company in Richmond, B.C. to develop “a durable hard coating to basically seal the implant,” a process he believes will be applicable to all mobile joints – hips, knees, ankles, and shoulders.

While implant failure rate is very low, Wang said the collaborative effort of orthopedic surgeons, pathologists, engineers, and scientists will continue to improve an already successful and life-changing technology.

Wang, Qiong, Felipe Eltit, Renfei Feng, Donald Garbuz, Clive Duncan, Bassam A. Masri, Nelson Greidanus, Michael E. Cox, and Rizhi Wang. "Nature of fretting corrosion products in CoCrMo hip implants from in vivo study to in vitro simulation." Materialia 22 (2022): 101433. https://doi.org/10.1016/j.mtla.2022.101433

Photos: Synchrotron | team members

Media Relations:

Victoria Schramm

Communications Coordinator

Canadian Light Source

306-657-3516

victoria.schramm@lightsource.ca